Cora Environment manages and operates the only privately-owned Energy-from-Waste (EfW) facility in Singapore that converts waste into energy, in the form of steam. This closes the loop by integrating waste collection, recovery, and steam generation in the energy-from-waste value chain.

Waste from our Industrial and Commercial sectors, including non-recyclables from our Material Recovery Facility, are sent to our EfW plant for incineration. This generates high-pressure steam which is then supplied to industrial businesses in Jurong Island via a steam network, lowering carbon emissions by 50% as compared to traditional fuel coal-fired steam plants.

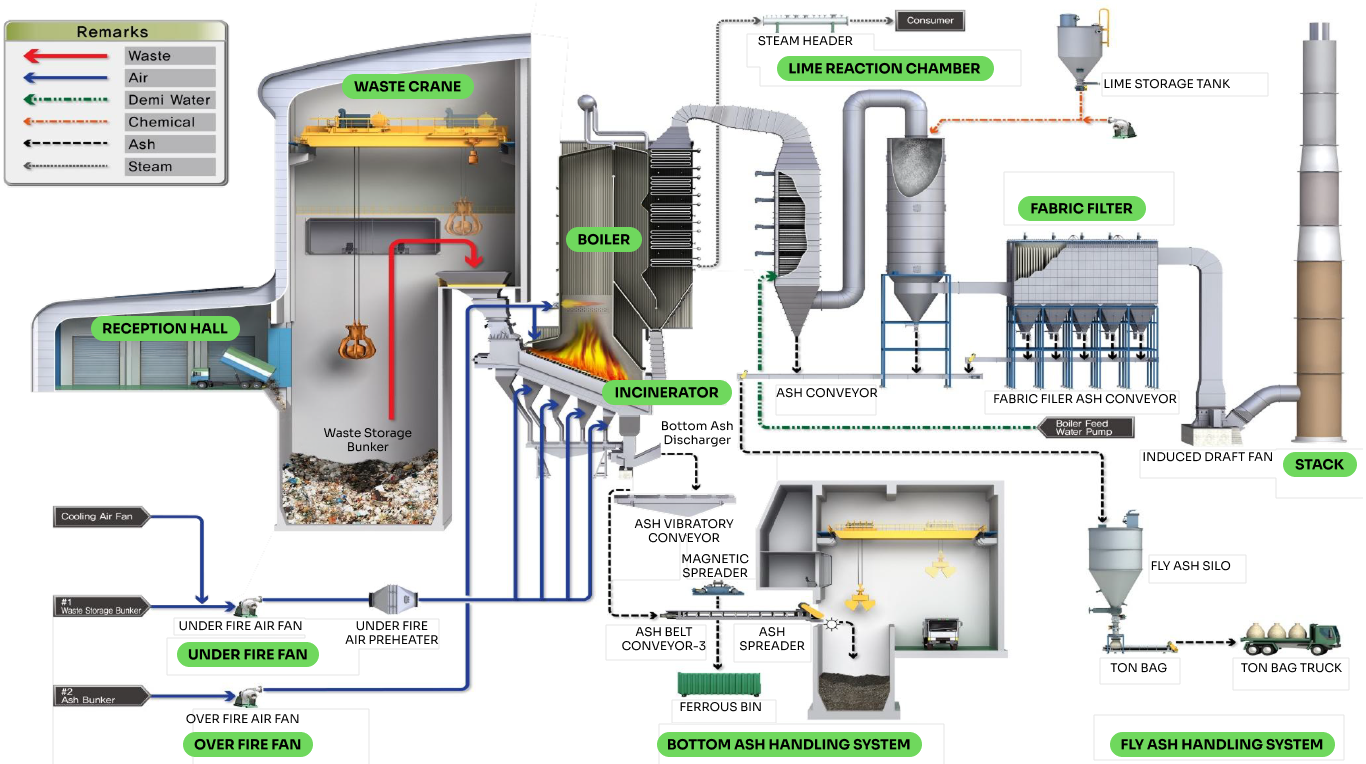

This is how our production process looks like:

From waste collection to steam generation

Efficiency

Carbon Footprint

Processing Capacity / Area

Leachate Treatment

Waste Water Treatment

Lower facility efficiency

Higher energy losses through double conversion of energy (Waste>Steam>Electricity)

Leachate treatment

Disposal into PUB sewer for further treatment

Waste water pre-treatment

Disposal into PUB sewer for further treatment

Efficiency

Carbon Footprint

Processing Capacity / Area

Leachate Treatment

Waste Water Treatment

Lower facility efficiency

Higher energy losses through double conversion of energy (Waste>Steam>Electricity)

Leachate treatment

Disposal into PUB sewer for further treatment

Waste water pre-treatment

Disposal into PUB sewer for further treatment